Industrial Technology

Connecting Technology Through People

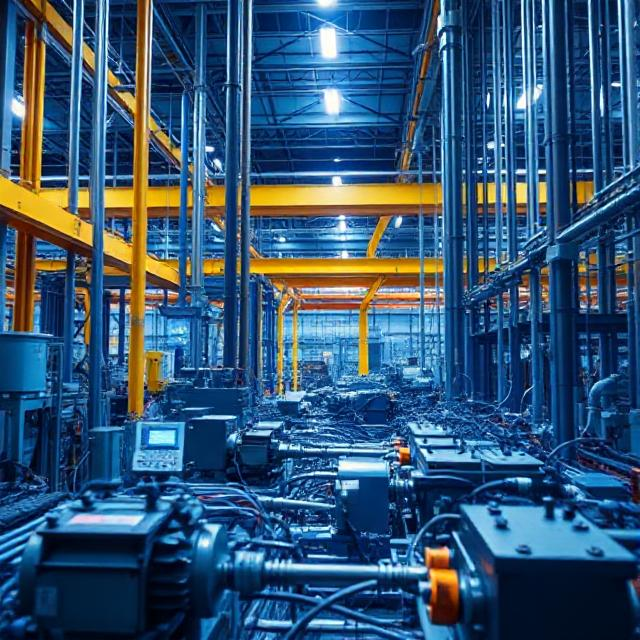

White Pearl Technology Group transforms industrial infrastructure through comprehensive technology solutions that span water treatment, mining operations, and industrial automation. Our proven implementations across major infrastructure projects demonstrate deep expertise in managing complex industrial environments that demand precise control, monitoring, and optimisation.

Core Industrial Solutions

Water Treatment Technology

Our water treatment solutions have revolutionised major infrastructure projects including the Suikerbosch Pumping Station and North Eastern Waste-Water Treatment Works. We implement advanced process control systems that manage treatment capacities exceeding 600 megalitres per day through sophisticated automation and monitoring. Our solutions incorporate real-time water quality monitoring that ensures consistent compliance with regulatory requirements while optimising treatment processes. We deploy automated chemical dosing systems that maintain precise control over treatment parameters while reducing operational costs. Through digital twin modelling, we enable comprehensive process simulation that enhances operational decision-making and optimisation.

Mining Infrastructure Solutions

Drawing from our experience at facilities like Klipspruit Mine and Grootegeluk Coal Mine, we deliver comprehensive technology solutions that transform mining operations. Our automated pollution control systems maintain continuous monitoring and management of environmental impacts while ensuring regulatory compliance. We implement smart stormwater management systems that handle variable conditions while protecting the environment. Our environmental monitoring networks provide real-time visibility into operational impacts while enabling proactive management. The integration of substation automation and control systems ensures reliable power distribution while optimising energy consumption.

Industrial Automation

Our industrial automation expertise spans diverse infrastructure projects, delivering consistent improvements in operational efficiency and reliability. We implement process control systems that maintain 99.9% uptime through redundant architectures and predictive maintenance. Our HVAC automation solutions optimise environmental conditions while reducing energy consumption by 20-30%. The integration of advanced fire protection systems ensures safety while minimising false alarms through intelligent monitoring. Our power distribution systems incorporate smart monitoring and control that improves reliability while reducing energy costs.

Implementation Framework

System Integration

We ensure seamless integration of new technologies with existing infrastructure through carefully planned implementation strategies. Our integration frameworks enable real-time data synchronisation across multiple platforms while maintaining system stability. The deployment of advanced analytics platforms provides actionable insights that drive continuous performance improvement. Our IoT sensor networks deliver comprehensive monitoring capabilities while ensuring reliable data collection and transmission.

Process Control

Our centralised control architectures provide comprehensive oversight while maintaining operational flexibility. We implement redundant systems for critical processes that ensure continuous operation even during system failures. The integration of real-time performance monitoring enables immediate response to operational variations while maintaining optimal performance. Our predictive maintenance systems reduce downtime through early issue detection and intervention. The implementation of emergency response automation ensures rapid and appropriate responses to critical situations.

Environmental Monitoring

We deploy continuous emissions monitoring systems that ensure regulatory compliance while enabling proactive environmental management. Our water quality tracking systems maintain constant oversight of treatment processes while optimising resource usage. The implementation of automated reporting systems reduces administrative burden while ensuring accurate and timely compliance reporting. Our trend analysis and forecasting capabilities enable proactive management of environmental impacts through data-driven insights.

Demonstrated Outcomes

Operational Excellence

Our implementations consistently deliver substantial improvements in operational performance and efficiency. Process efficiency typically improves by 30-40% through optimisation of control systems and operational parameters. System availability consistently exceeds 99.9% through redundant architectures and predictive maintenance. We achieve maintenance cost reductions of 25-35% through condition-based maintenance and predictive analytics. Energy efficiency improvements of 20-30% are realised through optimisation of control systems and operational parameters.

Infrastructure Impact

Our solutions deliver measurable improvements in infrastructure performance and reliability. Treatment facilities achieve capacities of up to 600 megalitres per day while maintaining consistent quality standards. Pollution reduction typically reaches 50-60% through improved control and monitoring systems. Resource recovery rates exceed 85% through the optimisation of recovery processes and control systems. Equipment lifespan increases by approximately 25% through improved maintenance and operational practices. Operating costs are typically reduced by 30% through automation and optimisation of processes.

Contact our Industrial Technology team to explore transforming your industrial operations while maintaining a focus on human-centred implementation.